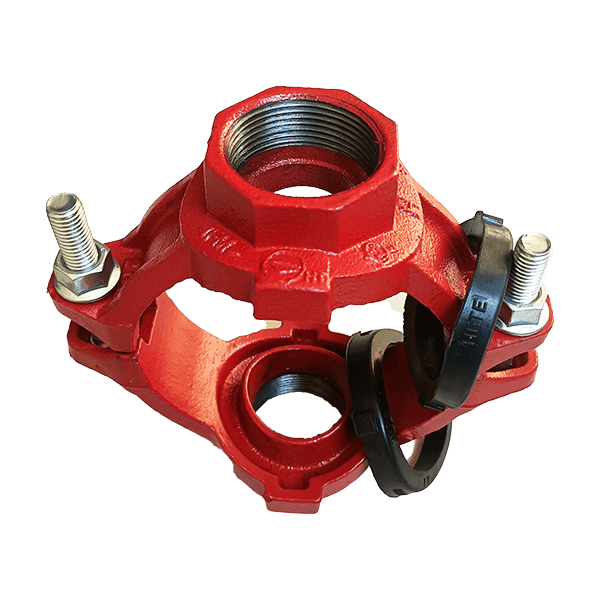

Grooved rigid coupling is a pipe fitting used to connect two pipes or equipment in various applications. It offers easy and fast installation without the need for any special tools or skills.

Features

- The grooved rigid coupling allows for flexible and quick installation without the use of special tools.

- High flexibility: the use of grooved couplings provides flexibility in piping systems, allowing for angular and axial movement between connected pipes or equipment.

- Strong versatility: the ductile iron grooved fittings is suitable for connecting pipes made of different materials, including steel, copper, plastic, and stainless steel.

Recommended Applications

Grooved rigid coupling is widely used in various piping systems made of different materials, such as water supply, drainage, HVAC, and other systems requiring pipe connections.

Key Specifications

- Available sizes: 1~12 inch | DN25~DN300

- Working pressure: 300PSI/2.07MPa

- Certificate: FM/UL/CE certified

- Coating: epoxy/galvanized

- Color: red/orange/white, etc.

- Material: ductile iron

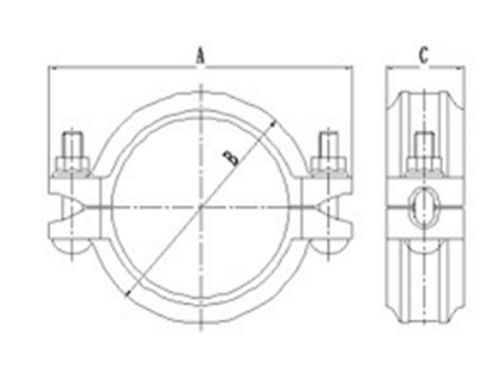

Specifications

| Nominal Size | Pipe OD | Dimensions | Bolt Size | ||

| mm/in | mm/in | mm/in | No.-Size mm | ||

| A mm/in | B mm/in | C mm/in | |||

| 25/1 | 33.7/1.327 | 58/2.28 | 98/3.85 | 45/1.77 | 3/8*45-2 |

| 32/(1 1/4) | 42.4/1.669 | 68/2.68 | 106/4.17 | 45/1.77 | 3/8*45-2 |

| 40/(1 1/2) | 48.3/1.9 | 74/2.91 | 114/4.49 | 45/1.77 | 3/8*45-2 |

| 50/2 | 60.3/2.375 | 86/3.39 | 128/5.04 | 45/1.77 | 3/8*55-2 |

| 65/(1 1/2) | 73/2.875 | 98/3.86 | 137/5.39 | 45/1.77 | 3/8*55-2 |

| 65/(1 1/2) | 76.1/3 | 98/3.86 | 141/5.55 | 45/1.77 | 3/8*55-2 |

| 80/3 | 88.9/3.5 | 112/4.41 | 155/6.10 | 45/1.77 | 3/8*55-2 |

| 100/4 | 108/4.25 | 140/5.51 | 189/7.44 | 50/1.96 | 1/2*65-2 |

| 100/4 | 114.3/4.5 | 140/5.51 | 192/7.56 | 50/1.96 | 1/2*65-2 |

| 125/5 | 133/5.25 | 164/6.46 | 216/8.5 | 50/1.96 | 1/2*75-2 |

| 125/5 | 139.7/5.5 | 166/6.54 | 217/8.54 | 50/1.96 | 1/2*75-2 |

| 125/5 | 141.3/5.563 | 173/6.81 | 225/8.86 | 50/1.96 | 1/2*75-2 |

| 150/6 | 159/6.25 | 193/7.59 | 246/9.69 | 50/1.96 | 1/2*75-2 |

| 150/6 | 165.1/6.5 | 199/7.83 | 252/9.92 | 50/1.96 | 1/2*75-2 |

| 150/6 | 168.3/6.625 | 197/7.76 | 244/9.61 | 48/1.89 | 1/2*75-2 |

| 200/8 | 219.1/8.625 | 255/10.04 | 322/12.67 | 58/2.28 | 5/8*95-2 |

| 250/10 | 273/10.75 | 318/12.51 | 400/15.74 | 62/2.44 | 3/4*110-2 |

| 300/12 | 323.9/12.75 | 372/14.64 | 454/17.87 | 64/2.51 | 3/4*120-2 |

What are the advantages of grooved rigid couplings?

Grooved rigid couplings offer advantages such as easy installation and maintenance, compact structure, light weight, reliability, durability, and cost-effectiveness.

What is a grooved rigid coupling used for?

A grooved rigid coupling is a common pipe fitting used in building piping systems, industrial conveying piping systems, fire protection piping systems, etc., providing convenience for the installation and maintenance of piping systems.

Why choose grooved rigid or flexible couplings for fire sprinklers and other fire protection systems?

Grooved rigid and flexible couplings are among the most important equipment in the fire protection field. They enable quick and waterproof connections without the need for welding, threading, or using flanges, making installation convenient and reducing potential risks during the installation process.

Related Products

Get in Touch

Find Your Application