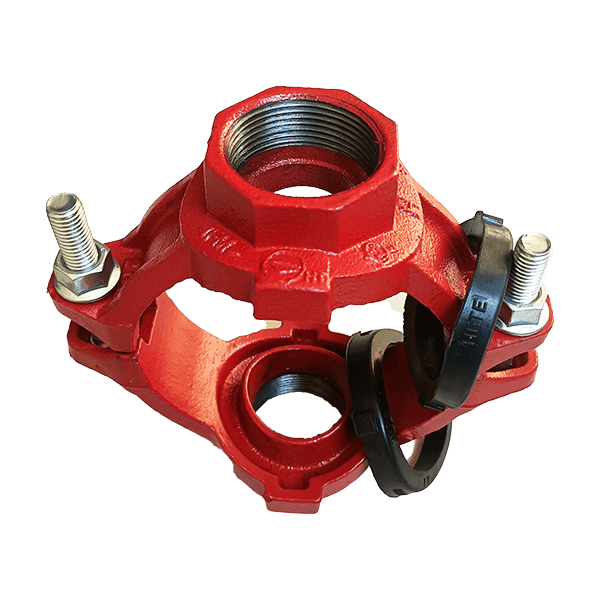

Grooved flexible coupling is a pipe fitting used for connecting pipes in a piping system. Flex couplings offer flexibility, allowing for axial displacement and angular deflection of the connected pipes, making the pipeline system more flexible. They are suitable for situations where pipes may become asymmetric or deformed due to temperature variations, vibrations, noise, etc., and can also be used to design curved pipe layouts.

Recommended Applications

Grooved flexible couplings are suitable for connecting medium-pressure piping systems, such as process pipelines, mining and oil field pipelines, etc.

Key Specifications

- Available sizes: 1~12 inch |DN25~DN300

- Working pressure: 300PSI/2.07MPa

- Certificate: FM/UL/CE certified

- Coating: epoxy/galvanized

- Color: red/orange/white, etc.

- Material: ductile iron

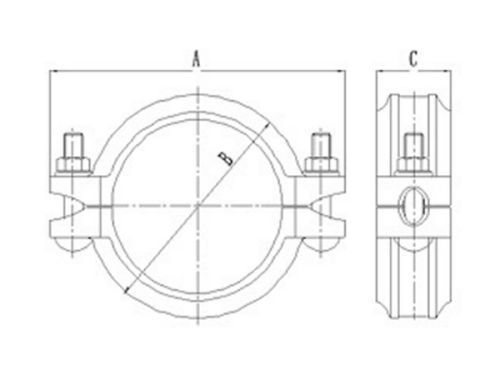

Specifications

| Nominal Size | Pipe OD | Dimensions | Bolt Size | ||

| mm/in | mm/in | mm/in | No.-Size mm | ||

| A mm | B mm | C mm | |||

| 25/1 | 33.7/1.327 | 58/2.28 | 98/3.85 | 45/1.77 | 3/8*45-2 |

| 32/(1 1/4) | 42.4/1.669 | 68/2.68 | 106/4.17 | 45/1.77 | 3/8*45-2 |

| 40/(1 1/2) | 48.3/1.9 | 74/2.91 | 114/4.49 | 45/1.77 | 3/8*45-2 |

| 50/2 | 60.3/2.375 | 86/3.39 | 126/4.96 | 45/1.77 | 3/8*55-2 |

| 65/(2 1/2) | 73/2.875 | 98/3.86 | 137/5.39 | 45/1.77 | 3/8*55-2 |

| 65/(2 1/2) | 76.1/3 | 98/3.86 | 140/5.51 | 45/1.77 | 3/8*55-2 |

| 80/3 | 88.9/3.5 | 111/4.37 | 158/6.22 | 45/1.77 | 3/8*55-2 |

| 100/4 | 108/4.25 | 130/5.11 | 180/7.09 | 49/1.93 | 1/2*65-2 |

| 100/4 | 114.3/4.5 | 141/5.55 | 186/7.32 | 49/1.93 | 1/2*65-2 |

| 125/5 | 133/5.25 | 164/6.46 | 216/8.5 | 50/1.96 | 1/2*75-2 |

| 125/5 | 139.7/5.5 | 168/6.61 | 222/8.74 | 50/1.96 | 1/2*75-2 |

| 125/5 | 141.3/5.563 | 172/6.77 | 222/8.74 | 50/1.96 | 1/2*75-2 |

| 150/6 | 159/6.25 | 190/7.48 | 236/9.29 | 50/1.96 | 1/2*75-2 |

| 150/6 | 165.1/6.5 | 196/7.71 | 244/9.61 | 50/1.96 | 1/2*75-2 |

| 150/6 | 168.3/6.625 | 197/7.76 | 244/9.61 | 50/1.96 | 1/2*75-2 |

| 200/8 | 219.1/8.625 | 251/9.88 | 318/12.52 | 58/2.28 | 5/8*95-2 |

| 250/10 | 273/10.75 | 318/12.51 | 386/15.20 | 60/2.36 | 3/4*110-2 |

| 300/12 | 323.9/12.75 | 372/14.64 | 454/17.87 | 64/2.51 | 3/4*120-2 |

What are the advantages of grooved flexible couplings?

Grooved flexible couplings offers the ability to reduce stress and vibration, minimize noise and wear, absorb shocks, impacts, or torsional loads, and compensate for thermal expansion or contraction, maintaining the piping system in good condition.

How to select the right pipe coupling?

In general, grooved rigid couplings are suitable for applications with good and stable shaft alignment and uniform loads, while grooved flexible couplings are most suitable for applications with moderate shaft misalignment and variable dynamic loads.

What are the benefits of a grooved piping system?

Grooved pipe fittings and couplings made of ductile iron are robust and durable, providing strength and durability. The combination of flexible couplings and gaskets can suppress vibrations, reducing damage to the connections and joints of piping system, thus reducing the need for repairs.

Related Products

Get in Touch

Find Your Application