Grooved Pipe Fittings for Oil Exploration Project

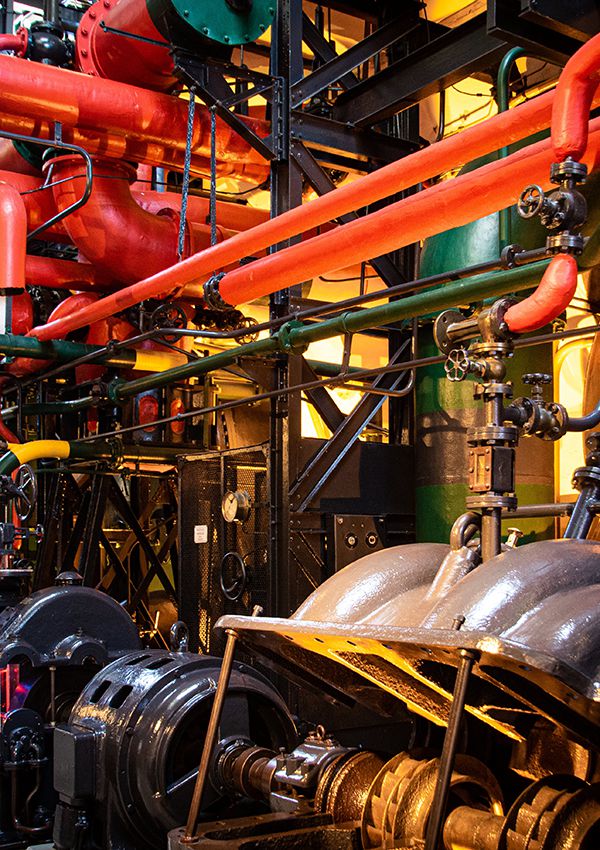

Grooved piping system changes the design, installation, and maintenance of oil transportation pipeline systems

With years of experience in grooved piping systems and numerous projects involving transportation pipelines, HT Casting can provide more reliable, efficient, and safe pipeline connections for oil and natural gas transportation projects.

Advantages of using grooved fittings in oil pipeline systems

Enhanced safety and efficiency

- Faster installation of oil pipeline with minimal manual tools required.

- Flame-free joining methods reduce potential hazards.

- No need for specialized welding personnel.

- Enhances worker safety and productivity.

Improved quality and reliability

- Grooved fittings undergo 100% quality inspection before leaving the factory.

- No need for specialized tools for post-installation testing; visual inspection is sufficient to validate the correctness of the installation.

- Flexibility of grooved fittings overcomes various construction difficulties.

Ensured project certainty

- Reduced operating costs (maintenance and expansion).

- Quick deployment of pipeline systems ensures projects can operate according to scheduled plans.

- Grooved piping systems are easier to maintain, reducing downtime risks for oil exploration.

Recommended Pipe Couplings & Fittings

-

View More

View More- Grooved Rigid Coupling Grooved rigid coupling is a pipe fitting used to connect two pipes or equipment in various applications. It offers easy and fast installation without the need for any special tools or skills.

-

Available sizes: 1~12 inch | DN25~DN300

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

View More- Grooved Concentric Reducer Grooved concentric reducers are cone-shaped pipe fittings with grooved connections that reduce the size of a pipeline in a symmetrical and concentric manner, while keeping the centerlines of the two pipes aligned.

-

Available sizes: 1 1/4×1 inch~12×10 inch |DN32×25~DN300×250

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

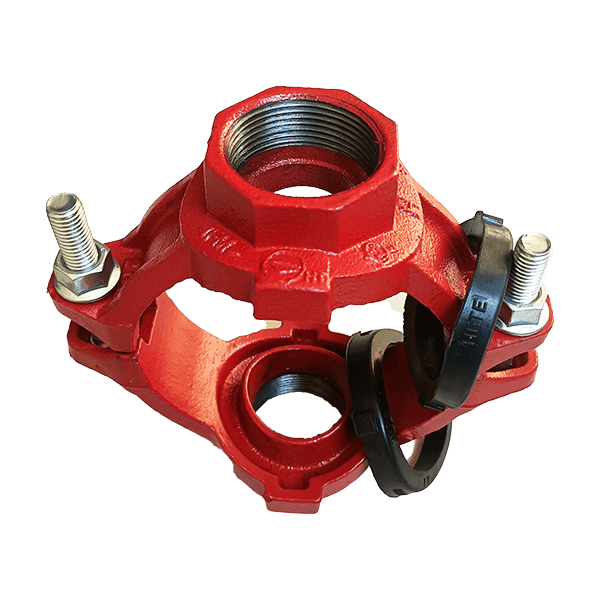

View More- Mechanical Tee Grooved Outlet Mechanical tee grooved outlet consist of upper and lower plates, a gasket, and bolts/nuts, providing a simple and fast method for branch connection.

-

Available sizes: 2×1 inch~10×4 inch |DN50×25~DN250×65

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

View More- Grooved Equal Tee The grooved ends are connected to the pipe using couplings for fluid distribution to provide the change in direction, and adapt sizes or components.

-

Available sizes: 1 inch~12 inch |DN25~DN300

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

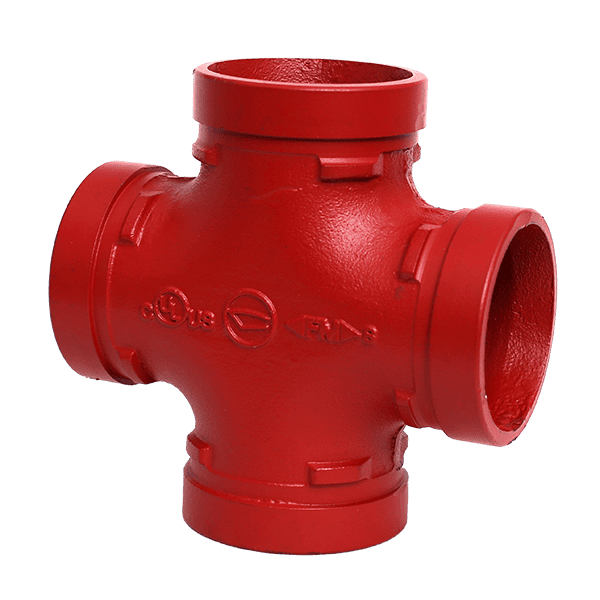

View More- Grooved Equal Cross Grooved equal cross features convenient and quick connections utilizing a coupling. Simply insert the pipe into the coupling and tighten the bolts.

-

Available sizes: 2 inch~8 inch |DN50~DN200

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

View More- Grooved 90° Elbow Grooved 90°elbow is an elbow fitting that is used for connecting two pipes with the same size to make the pipeline turn 90 degrees. It provides a change in flow direction and facilitates the adaptation of sizes or components.

-

Available sizes: 1 1/4×1 inch~8×6 inch |DN32×25~DN200×150

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

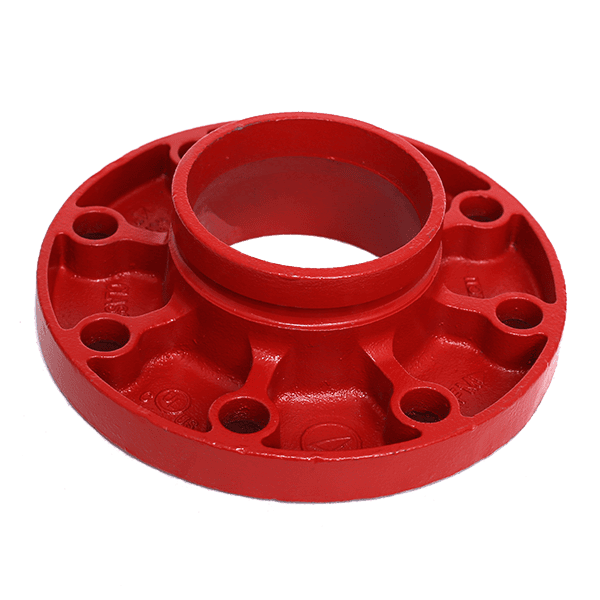

View More- Grooved Adaptor Flange A grooved adaptor flange is an adjustable connecting flange that functions similarly to an expansion joint. It consists of two flange discs that are individually fixed, with a flange gasket placed between them.

-

Available sizes: 1 inch~12 inch |DN25~DN300

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-

-

View More

View More- Grooved End Cap A grooved end cap is specifically designed to be fitted onto the end of a pipe using a grooved connection. It serves as an isolation or cutoff device to block the pipeline and form liquid or gas tight seal.

-

Available sizes: 1 inch~12 inch |DN25~DN600

-

Working pressure: 300 PSI

-

Certificate: FM/UL/CE certified

-