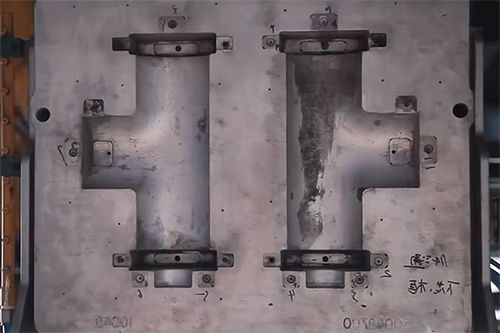

Grooved Fittings Manufacturing

-

-

- Spray painting The thermal spraying process can be divided into four steps: workpiece surface pretreatment → workpiece preheating → spraying → post-treatment of coating. The following is a step-by-step explanation.

- Surface pretreatment: in order to ensure good adhesion between the coating and the substrate material, the substrate surface must be cleaned and roughened. The method of cleaning and roughening the surface depends on factors such as coating requirements, substrate conditions, and construction conditions.

- Preheating: preheating is done to eliminate moisture on the surface of the workpiece, increase the interface temperature, and improve the bonding strength between the coating and the substrate, reducing coating cracking. Generally, preheating temperature is controlled between 60-120 ℃.

- Spraying

- Post-treatment of the coating.

-

Inspection steps

- Source guarantee Each batch of raw materials must pass the quality checking before being allowed into the factory.

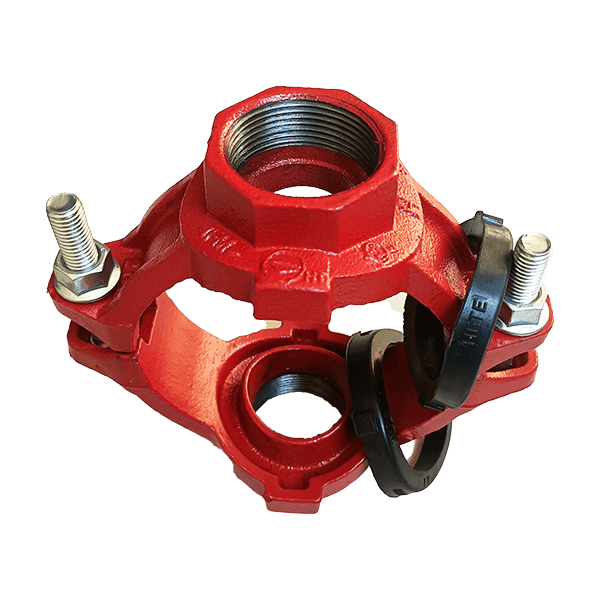

- Reliable components All bolts & nuts, gaskets and packing materials must be checked on the inbound.

- High standard of melting process every forge of melted iron must go through the CE chemical analysis before the casting process, ensuring high quality, high-quality molten iron.

- Spheroidization analysis Each batch of tests must ensure that the spheroidization level of molten iron is at least level 3 or above before being allowed to go offline.

- Metallographic checking 100% double checked, 100% insurance of spheroidization.

- Production transaction checking The director of the relevant workshop must give approval before it can proceed to the next step.

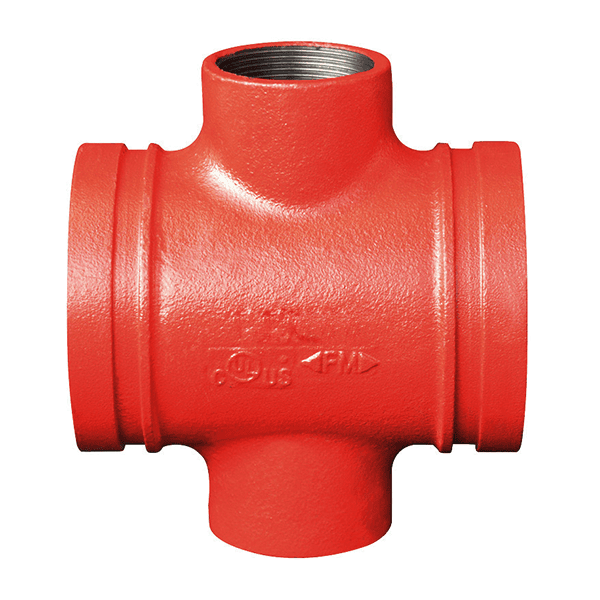

- Black parts inspection Individual piece must pass the black parts checking to ensure no sand holes, no inclusion. This ensures high quality and quantity!

- Air tightness testing Each pipe fitting product is individually pressurized and inspected.

- Dimensional inspection Daily random sampling inspection is conducted, ensuring quality for every batch!

- Mechanical performance testing Random sampling inspection is conducted following 3C/FM/UL standards. High pressure, static pressure, and bending moment tests are conducted daily. No damage occurs under 10MPa destructive pressure test!

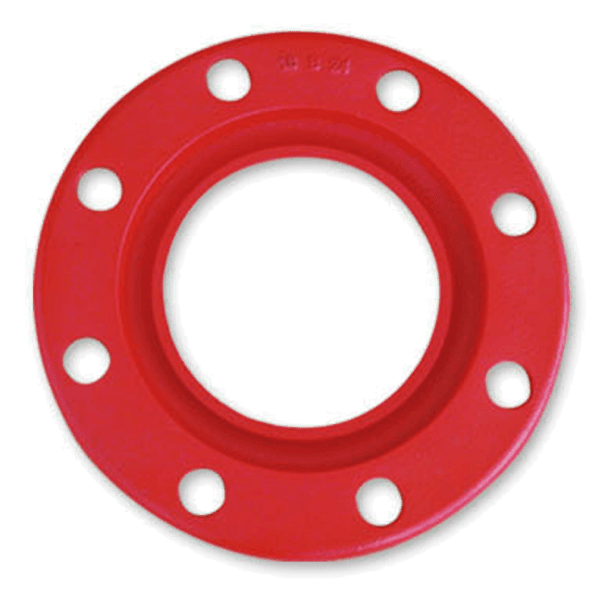

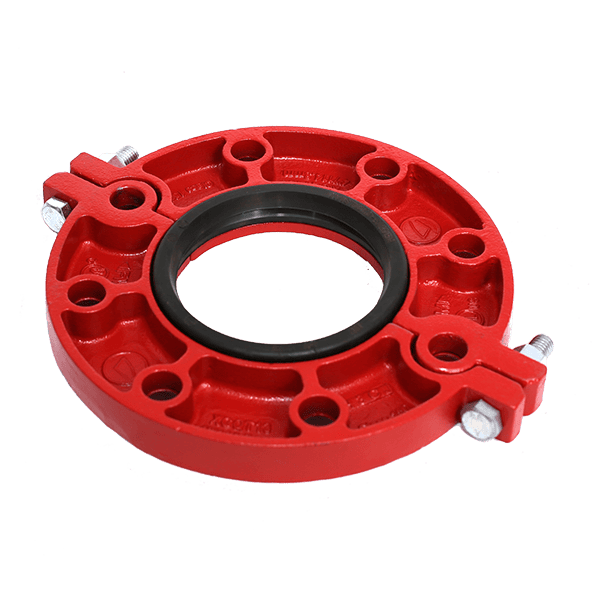

- Visual inspection of coating Professional coating quality inspection ensures quality for each product.

- 6S inspection Random inspection is conducted during unpacking by 6S patrol team, at least 3 times a week!