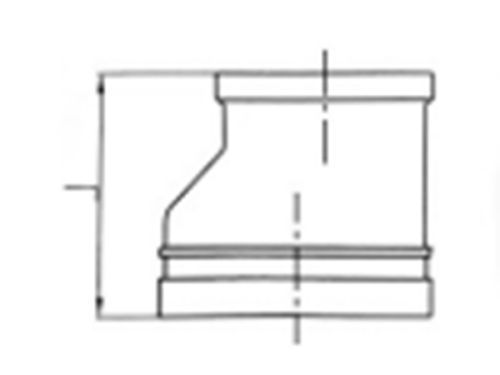

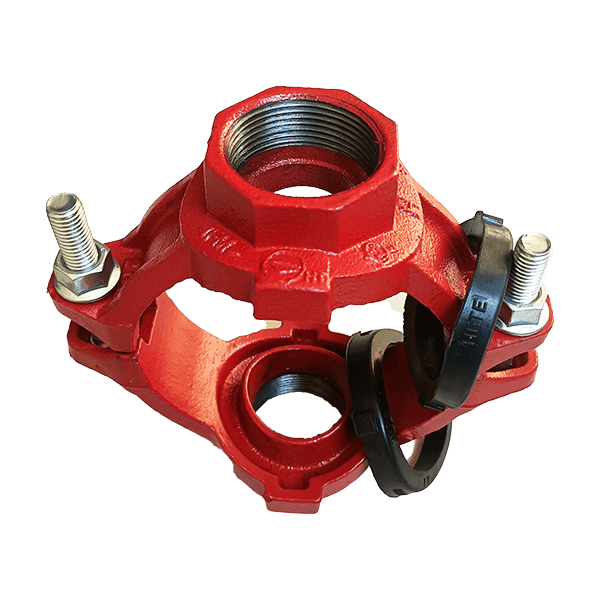

Threaded eccentric reducers are cone-shaped pipe fittings with grooves and internal threads for pipe connection, reducing the size of the pipeline in an eccentric manner. This pipe reducer achieves mechanical coupling by using a set of grooves at the ends of the pipes and fittings. Typically, a specialized tool is used to cut a groove at one end of the pipe, and then the joint is clamped onto the groove using bolts or a similar mechanism. The other end is threaded.

Features

- Typically made of ductile iron, stainless steel, or carbon steel, which provide strong wear resistance and corrosion resistance.

- Available in various sizes and pressure ratings, suitable for different applications.

- Enables the connection of two pipes with different diameters.

Recommended Applications

Threaded eccentric reducers are commonly used in industrial and commercial piping systems, such as gas pipelines, water supply pipelines, etc., where the size of the pipeline needs to be reduced to accommodate changes in flow or pressure.

Key Specifications

- Available sizes: 1 1/4×1 inch~12×4 inch |DN32×25~DN300×100

- Working pressure: 300PSI/2.07MPa

- Certificate: FM/UL/CE certified

- Coating: epoxy/galvanized

- Color: red/orange/white

- Material: ductile iron

Specifications

| Nominal Size | Pipe OD | Dimensions |

| mm/in | mm/in | L mm/in |

| 32x25 / 1 1/4x1 | 42.4x33.7 / 1.660x1.315 | 64 / 2.51 |

| 40x25 / 11/2x1 | 48.3x33.7 / 1.900x1.315 | 64 / 2.51 |

| 40x32 / 1 1/2×1 1/4 | 48.3x42.4 / 1.900x1.660 | 64 / 2.51 |

| 50x25 / 2x1 | 60.3 x 33.7 / 2.375x1.315 | 64 / 2.51 |

| 50x32 / 2x1 1/4 | 60.3x42.4 / 2.375x1.660 | 64 / 2.51 |

| 50x40 / 2x1 1/2 | 603x48.3 / 2.375x1.900 | 64 / 2.51 |

| 65x25 / 2 1/2x1 | 73.0 x 33.7 / 2.875x1.315 | 64 / 2.51 |

| 65x32 / 2 1/2x1 1/4 | 73.0x42.4 / 2.875x1.660 | 64 / 2.51 |

| 65x40 / 2 1/2x1 1/2 | 73.0x48.3 / 2.875x1.900 | 64 / 2.51 |

| 65x50 / 2 1/2x2 | 73.0 x 60.3 / 2.875x2.375 | 64 / 2.51 |

| 65x32 / 2 1/2x1 1/4 | 76.1 x 42.4 / 3.000x1.660 | 64 / 2.51 |

| 65x40 / 2 1/2x1 1/2 | 76.1x48.3 / 3.000x1.900 | 64 / 2.51 |

| 65x50 / 2 1/2x2 | 76.1x60.3 / 3.000 x 2.375 | 64 / 2.51 |

| 80x32 / 3x1 1/4 | 88.9x42.4 / 3.500x1.660 | 55 / 2.17 |

| 80x40 / 3x1 1/2 | 88.9 x 48.3 / 3.500x1.900 | 55 / 2.17 |

| 80x50 / 3x2 | 88.9 x 60.3 / 3.500x2.375 | 55 / 2.17 |

| 80x65 / 3x2 1/2 | 88.9x76.1 / 3.500 x 3.000 | 55 / 2.17 |

| 100x65 / 4x2 1/2 | 108.0 x 76.1 / 4.250 x 3.000 | 76 / 2.99 |

| 100x80 / 4x3 | 108.0x88.9 / 4.250 x 3.500 | 76 / 2.99 |

| 100x32 / 4x1 1/4 | 114.3x42.4 / 4.500x1.660 | 60 / 2.36 |

| 100x40 / 4x1 1/2 | 114.3x48.3 / 4.500x1.900 | 60 / 2.36 |

| 100x50 / 4x2 | 114.3x60.3 / 4.500x2.375 | 60 / 2.36 |

| 100x65 / 4x2 1/2 | 114.3x76.1 / 4.500 x 3.000 | 60 / 2.36 |

| 100x80 / 4x3 | 114.3x88.9 / 4.500 x 3.500 | 60 / 2.36 |

| 125x50 / 5x2 | 139.7x60.3 / 5.500x2.375 | 65 / 2.56 |

| 125x65 / 5x2 1/2 | 139.7x76.1 / 5.500 x 3.000 | 65 / 2.56 |

| 125x80 / 5x3 | 139.7x88.9 / 5.500 x 3.500 | 65 / 2.56 |

| 125x100 / 5x4 | 139.7x114.3 / 5.500 x 4.500 | 65 / 2.56 |

| 150x50 / 6x2 | 159.0x60.3 / 6.250x2.375 | 70 / 2.76 |

| 150x65 / 6x2 1/2 | 159.0x76.1 / 6.250 x 3.000 | 70 / 2.76 |

| 150x80 / 6x3 | 159.0x88.9 / 6.250 x 3.500 | 70 / 2.76 |

| 150x100 / 6x4 | 159.0x108.0 / 6.250 x 4.250 | 70 / 2.76 |

| 150x100 / 6x4 | 159.0x114.3 / 6.250x4.500 | 70 / 2.76 |

| 150x125 / 6x5 | 159.0x133.0 / 6.250x5.250 | 70 / 2.76 |

| 150x125 / 6x5 | 159 0x139 7 / 6.250 x 5.500 | 70 / 2.76 |

| 150x50 / 6x2 | 165.1 x60.3 / 6.500 x 2.375 | 102 / 4.01 |

| 150x65 / 6x2 1/2 | 165.1x76.1 / 6.500 x 3.000 | 102 / 4.01 |

| 150x80 / 6x3 | 165.1x88.9 / 6.500 x 3.500 | 102 / 4.01 |

| 150x100 / 6x4 | 165.1x114.3 / 6.500x4.500 | 102 / 4.01 |

| 150x125 / 6x5 | 165.1x139.7 / 6.500x5.500 | 102 / 4.01 |

| 150x50 / 6x2 | 168.3 x 60.3 / 6.625x2.375 | 70 / 2.76 |

| 150x65 / 6x2 1/2 | 168.3x76.1 / 6.625 x 3.000 | 70 / 2.76 |

| 150x80 / 6x3 | 168.3 x 88.9 / 6.625x3.500 | 70 / 2.76 |

| 150x100 / 6x4 | 168.3x114.3 / 6.625x4.500 | 70 / 2.76 |

| 150x125 / 6x5 | 168.3x139.7 / 6.625 x 5.500 | 70 / 2.76 |

| 200 x 50 / 8x2 | 219.1x60.3 / 8.625x2.375 | 85 / 3.35 |

| 200x65 / 8x2 1/2 | 219.1x76.1 / 8 625x3.000 | 85 / 3.35 |

| 200 x 80 / 8x3 | 219.1x88.9 / 8.625x3.500 | 85 / 3.35 |

| 200x100 / 8x4 | 219.1 x 108.0 / 8.625x4.250 | 85 / 3.35 |

| 200x100 / 8x4 | 219.1 x 114.3 / 8.625x4.500 | 85 / 3.35 |

| 200x125 / 8x5 | 219.1 x 139.7 / 8.625 x 5.500 | 85 / 3.35 |

| 200x150 / 8x6 | 219.1 x 159.0 / 8.625x6.250 | 85 / 3.35 |

| 200x150 / 8x6 | 219.1 x 165.1 / 8.625x6.500 | 85 / 3.35 |

| 200x150 / 8x6 | 219.1 x 168.3 / 8.625x6.625 | 85 / 3.35 |

Why is a grooved piping system considered easier to maintain?

In a grooved piping system, maintenance is as simple as loosening the bolts of the couplings and removing them from the joints to access the pipes. Unlike pipes with flange or welded connections, there is no need to cut or re-weld the pipes during maintenance, which significantly reduces maintenance costs.

What are the applications of mechanical piping connectors?

Mechanical piping connectors, known for their easy installation and maintenance, are commonly used in applications such as fire sprinkler piping systems, wastewater treatment piping systems in paper mills, and petroleum transportation piping systems.

Related Products

Get in Touch

Find Your Application