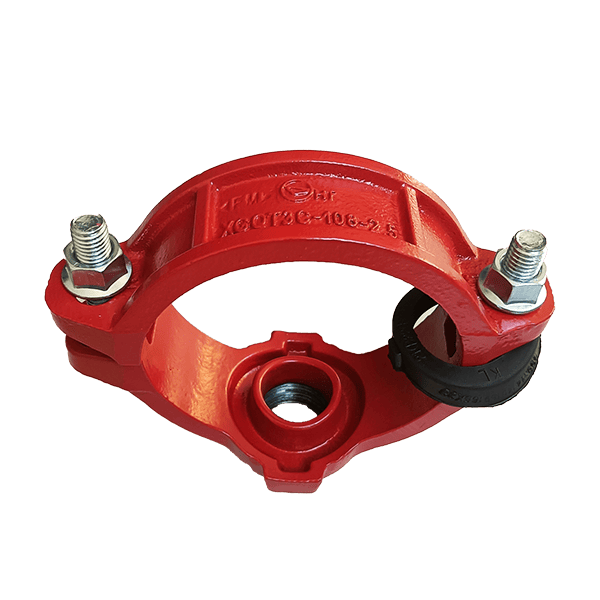

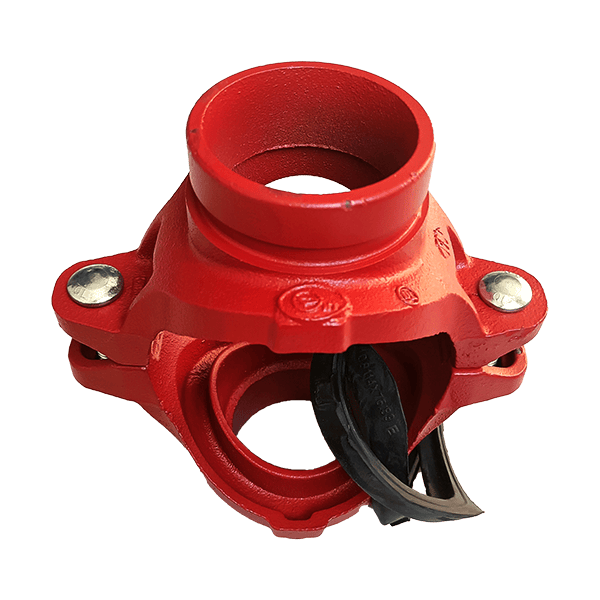

U-bolt mechanical tee consists of an upper housing and U-bolt/nuts, allowing for quick and simple connection of branch pipes to the main pipeline. Compared to traditional branch tees, it offers unparalleled advantages, such as fast installation and long-term reliability.

Features

- Just cut or drill a hole at the desired outlet location of the main pipe without the need for welding.

- Position the mechanical tee so that the built-in locating collar fits within the hole and is secured with the U-bolt and nuts.

- The mechanical tee allows a full bore flow pressure rated to 300 psi (20 bar).

Recommended Applications

U-bolt mechanical tee is the ideal outlet fitting for direct connections to sprinkler heads, drop nipples, and or gauges.

Key Specifications

- Available sizes: 1×1/2 inch~3×1 inch |DN25×15~DN80×25

- Working pressure: 300PSI/2.07MPa

- Certificate: FM/UL/CE certified

- Coating: epoxy/galvanized

- Color: red/orange/white, etc.

- Material: ductile iron

Specifications

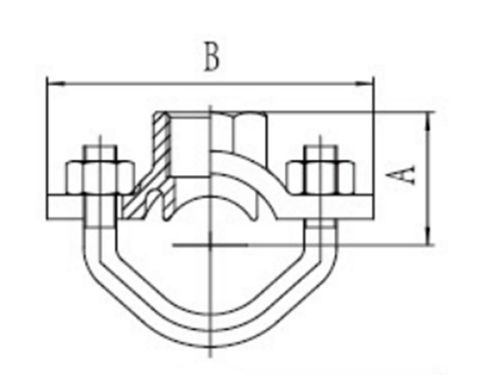

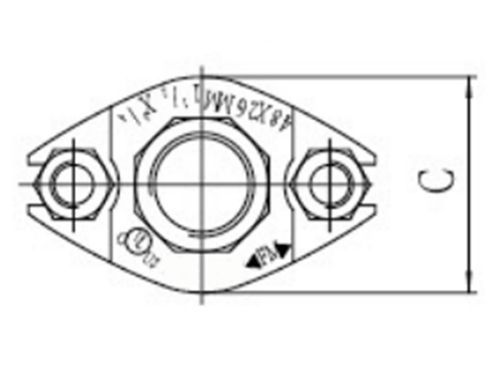

| Nominal Size | Pipe OD. | Hole Dia | Dimensions mm/m | Bolt Size | ||

| mm/in | mm/in | mm/in | A mm | B mm | C mm | mm |

| 25x15 / 1×1/2 | 33x21 / 1.327x0.825 | 30 / 1.18 | 35 / 1.38 | 80 / 3.15 | 56 / 2.2 | M10x33U |

| 25x20 / 1×3/4 | 33x27 / 1.327x1.050 | 30 / 1.18 | 40 / 1.57 | 80 / 3.15 | 56 / 2.2 | M10x33U |

| 32x15 / 1 1/4×1/2 | 42.4x21.3 / 1.660x0.825 | 30 / 1.18 | 43 / 1.69 | 90 / 3.54 | 56 / 2.2 | M10x42U |

| 32x20 / 1 1/4×3/4 | 42.4 x 26.9 / 1.660x1.050 | 30 / 1.18 | 43 / 1.69 | 90 / 3.54 | 56 / 2.2 | M10x42U |

| 32x25 / 1 1/4×1/2 | 42.4x33.7 / 1.660x1.315 | 30 / 1.18 | 51 / 2.01 | 90 / 3.54 | 56 / 2.2 | M10x42U |

| 40x15 / 1 1/2×1/2 | 48.3x21.3 1.900x0.825 | 30 / 1.18 | 46 / 1.81 | 90 / 3.54 | 56 / 2.2 | M10x48U |

| 40x20 / 1 1/2×3/4 | 48.3x26.9 / 1.900x1.050 | 30 / 1.18 | 46 / 1.81 | 90 / 3.54 | 56 / 2.2 | M10x48U |

| 40x25 / 1 1/2×1 | 48.3x33.7 1.900x1.315 | 30 / 1.18 | 54 / 2.13 | 90 / 3.54 | 56 / 2.2 | M10x48U |

| 50x15 / 2x1/2 | 60.3x21.3 / 2.375x0 825 | 30 / 1.18 | 52 / 2.05 | 96 / 3.78 | 56 / 2.2 | M10x60U |

| 50x20 / 2x3/4 | 60.3x26.9 / 2.375x1.050 | 30 / 1.18 | 52 / 2.05 | 96 / 3.78 | 56 / 2.2 | M10x60U |

| 50x25 / 2x1 | 60.3 x 33.7 2.375x1.315 | 30 / 1.18 | 60 / 2.36 | 96 / 3.78 | 56 / 2.2 | M10x60U |

| 65x15 / 2 1/2×1/2 | 73x21 / 2.874x0.825 | 30 / 1.18 | 60 / 2.36 | 112 / 4.41 | 56 / 2.2 | M10x73/76U |

| 65x20 / 2 1/2×3/4 | 73x27 / 2.874x1.050 | 30 / 1.18 | 60 / 2.36 | 112 / 4.41 | 56 / 2.2 | M10x73/76U |

| 65x25 / 2 1/2×1/2 | 73x33 / 2.874x1.315 | 30 / 1.18 | 68 / 2.68 | 112 / 4.41 | 56 / 2.2 | M10x73/76U |

| 65x15 / 2 1/2×1/2 | 76.1x21.3 / 3.000x0.825 | 30 / 1.18 | 60 / 2.36 | 112 / 4.41 | 56 / 2.2 | M10x73/76U |

| 65x20 / 2 1/2×3/4 | 76.1 x26.9 3.000x1.050 | 30 / 1.18 | 60 / 2.36 | 112 / 4.41 | 56 / 2.2 | M10x73/76U |

| 65x25 / 2 1/2×1/2 | 76.1 x33.7 / 3.000x1.315 | 30 / 1.18 | 68 / 2.68 | 112 / 4.41 | 56 / 2.2 | M10x73/76U |

| 80×15 / 3×1/2 | 88.9×21.3 / 3.500×0.825 | 38 / 1.50 | 70 / 2.76 | 144 / 5.67 | 74 / 2.91 | M12x89U |

| 80×20 / 3×3/4 | 88.9×26.7 / 3.500×1.050 | 38 / 1.50 | 70 / 2.76 | 144 / 5.67 | 74 / 2.91 | M12x89U |

| 80×25 / 3×1 | 88.9×33.7 / 3.500×1.315 | 38 / 1.50 | 75 / 2.95 | 144 / 5.67 | 74 / 2.91 | M12x89U |

What are mechanical Couplings?

Mechanical couplings are fittings used to connect two pipes together. Unlike traditional welded connections that require skilled labor and specialized equipment for installation, mechanical couplings can be easily installed using basic tools and minimal training.

What are the applications of mechanical couplings?

Mechanical couplings have a wide range of applications, including piping systems in manufacturing plants and industrial equipment, water treatment facilities, and oil transportation systems.

What are the advantages of using grooved fittings and mechanical couplings in a piping system?

By using these flame-free joining methods in a piping system, it offers increased installation speed, reduced potential risks during the pipe installation process, as well as minimized impact on the pipeline system due to thermal expansion, contraction, and geological vibrations, and lowered long-term maintenance cost.

Related Products

Get in Touch

Find Your Application